Production Planning and Scheduling

- Home

- Decision One Overview

- Production Planning and Scheduling

Decision One’s Production Planning & Controlling (PPC) Software Solutions is one of the unique software tools that enables manufacturing facilities efficient and effective Cut to Pack Operations Planning as well as Factory Line Planning.

Decision One Textile / Process Industry Solutions offers extremely visual, capacity planning and process modelling software solution which allows the textile process industries to match future demand against available capacity, manage their commitments and improve order confirmation process, work in progress and inventory levels.

Planning and coordinating textile production through the various processes of fabric production (Weaving/Knitting), dyeing and numerous finishing operations means that manufacture has to be tightly controlled.

The textile sector has so far managed all this complexity using spreadsheets and manual methods, very little else exists other than a few, short term machine schedulers that only look a few days ahead. As the fashion sector continues to focus on speed to market and supplier flexibility, the challenges of handling all this manually increase; Decision One provides a much needed alternative.

The PPC tool from DecisionOne facilitates garments, textile and leather manufactures to proactively plan and schedule their production operations in such a manner that could anticipate any bottlenecks and prevent them and act dynamically to address issues.

Highlights:

- Multi-level planning options for both long range capacity management and short term scheduling

- Allows you to coordinate fabric production, dyeing and finishing in a single system

- Calculation of required materials to meet the plan

- Flexible, management level reporting - fast access to information

- The plan is dynamic, so it's always updated to reflect current performance

Salient features of Decision One PPC:

- Model Your Factory: Begin with the production plant, add work centers/departments, and then incorporate lines/machines within them.

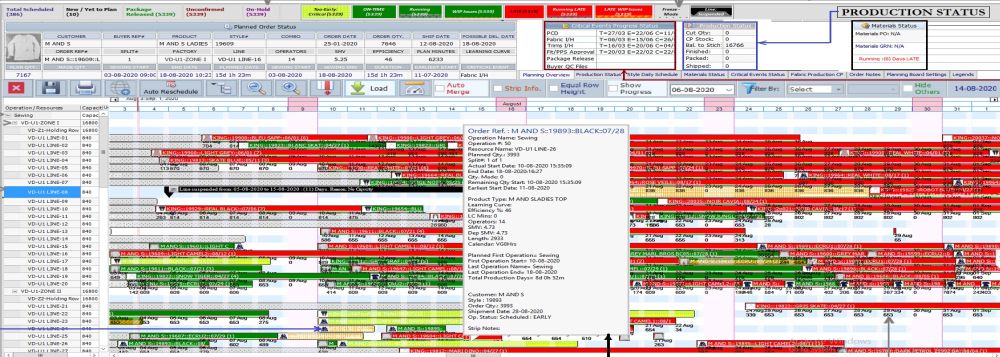

- Dynamic Sewing Line Allocation: Decision One streamlines machine allocation amidst daily fluctuations like leaves, holidays, and overtime, ensuring smooth factory scheduling and efficiency

- Add Orders - Automatic addition of customer orders to generate production schedules considering available machines. It can be efficiently integrate Decision One with your existing ERP or manually adding order is also possible

- Load Orders – Using Decision One, The Production Planner can easily plan the customer orders automatically or manually

- Drag-and-Drop - Planning an efficient production plan is just mouse-click away. Simple click and then drag-and-drop operations on the planning board and see the impact on your orders, enabling you to make informed decisions.

- Dynamic Line Transfers & Auto Schedule Features

- Automatic indicators will promptly alert about WIP bottlenecks, materials delay or shipment delay.

- Dynamic Split, Merge of Orders & Adjusting Planned Parameters ( Capacity Factor, Efficiency) and Adding or Removing Learning Curves

- Freeze / Unfreeze Functionality

- Adding / attaching comments or documents against Plan

- Grouping & Auto Sorting Of Planned Orders by Product/Style

- AutoSort and Schedule: by Delivery Dates or Material In-House Dates.

- Dynamic Find and Hide others by (Customer/Product/Style/SO)

- Dynamic Learning Curves – To Handle Slow Productions

- Booked Vs. Capacity Plan

- Actual vs. Plan

- Operation Bulletins (O.B)

- Order / Purchase / Fabric Executive Diary

- Micro Level Fabric Production Planning

- Real Time Warehouse Planning

- Demand Driven MRP (DD-MRP) with interface with Existing ERP

- Daily Machine / Operators Requirement Planning

- Operation Progress Report

- End-to-End Chart (Comprehensive Planning from Order Booking till Order Closure)

- Interactive Micro Loading Plan by Customer, Line, Factory and Region (Daily/Weekly/Monthly)

The Planner can effortlessly monitor the executive diaries, Fabric Production T&A, Material Order status and Materials in-house status to generate executable production plan by considering all constraints.

Why Decision One

Subscribe

Please subscribe to our mailing list for technology and business updates

We hereby promise to be responsible emailers.